Pharmaceutical Contract Manufacturing

Several challenges stand out in the modern pharmaceutical contract manufacturing (CDMO) industry. Given today’s pharmaceutical landscape, one can hardly overstate the importance of contracting with a capable partner for drug development – from pre-formulation to manufacturing.

-

One significant issue is ensuring regulatory compliance throughout the manufacturing process.

Pharmaceutical products are subject to stringent quality standards set by regulatory agencies. These requirements often add complexity and cost to manufacturing.

-

Another critical challenge is maintaining supply chain resilience.

Pharmaceutical manufacturing means that disruptions — such as geopolitical instability or raw material shortages — can impact production schedules and product availability. Selecting a U.S.-based CDMO for manufacturing has benefits.

-

Cost management is also critical.

Balancing the need for high-quality manufacturing with cost efficiency requires careful planning and optimization. Manufacturers must invest in advanced technologies and skilled labor while controlling expenses to remain competitive.

-

Intellectual property protection is crucial.

CDMOs often handle proprietary formulations and processes. This necessitates robust confidentiality agreements and security measures to safeguard client information.

-

Keeping pace with technological advancements is vital.

The industry continually evolves with new manufacturing techniques, automation, and digitalization. Staying ahead requires ongoing investment in innovation and adaptation to new technologies – staples in Ascendia’s philosophy.

Successfully navigating these challenges demands technical expertise, regulatory knowledge, strategic planning, and financial acumen.

Experience: The Key to Confidence

As a full-service specialty pharmaceutical CDMO operating in the United States, Ascendia Pharmaceutical Solutions stands out for its specialization in providing pharma and biotech companies with the unique combination of expertise and equipment required to successfully manufacture modern drugs.

Our capabilities range from small-scale clinical trial material supply batches to large-scale final dosage form production runs. This impressive level of versatility frequently sets Ascendia apart from our competitors.

Pharmaceutical Contract Manufacturing Services

Whether contracting Ascendia for the aseptic processing of parenteral dosage forms, manufacturing liquid filled capsules, emulsion, lipid nanoparticles, nanosuspension or amorphous solid dispersions, or supplying formulation for a low oral bioavailability drug, our biotech and pharma company partners rest assured. They know our highly skilled scientific team has the breadth and depth of experience necessary to deliver rapid, efficient, comprehensive, and flexible manufacturing programs.

Modern Facilities, Enhanced Capabilities

Ascendia's North Brunswick, New Jersey headquarters, houses a state-of-the-art manufacturing facility. Our facility is not just a manufacturing space; it's a hub of innovation and science.

Our New Jersey Bioscience Center headquarters boasts sterile manufacturing, ISO-5/7 process, and filling room space. Equipped with the latest technology and machinery, it's a testament to our commitment to staying at the forefront of the industry.

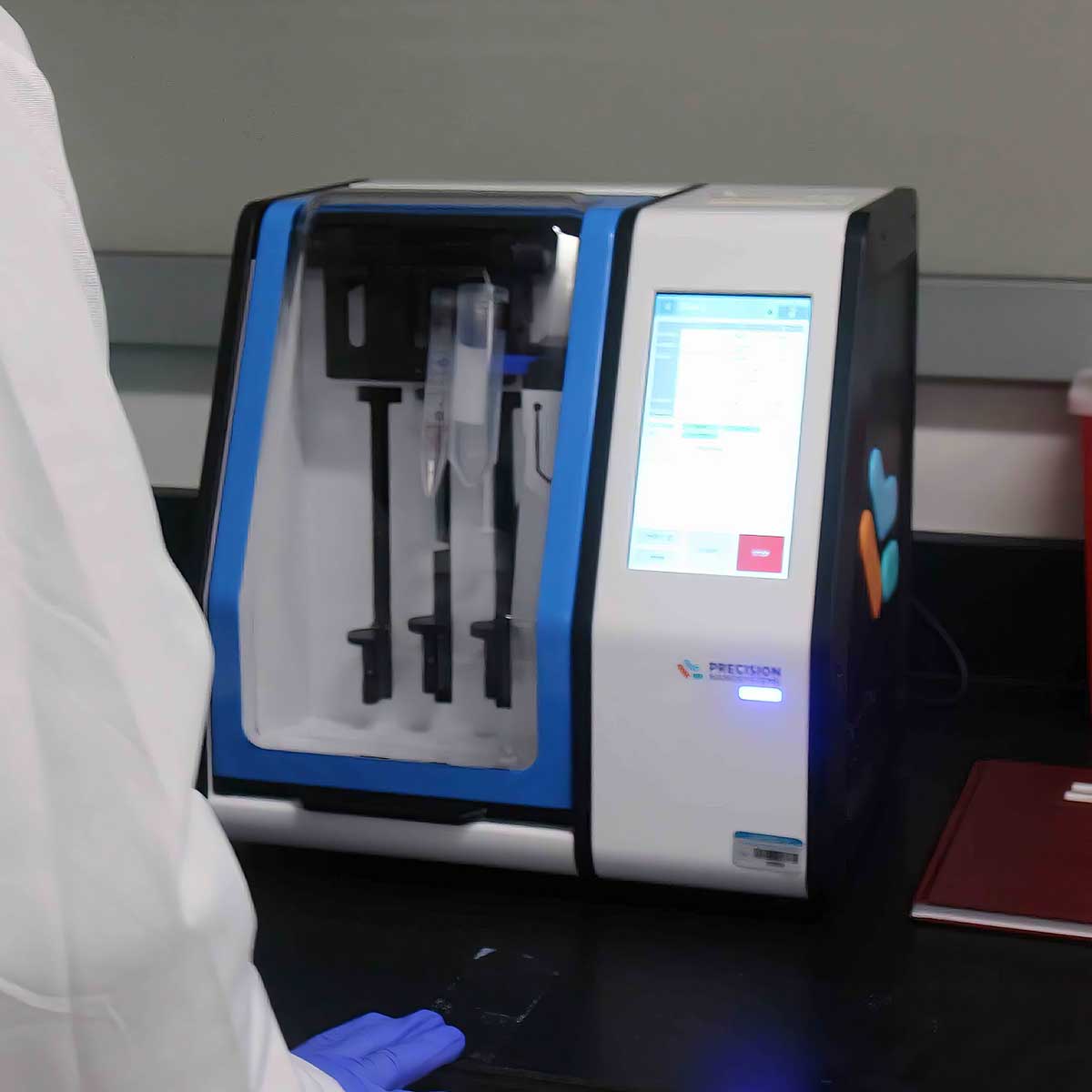

For example, Ascendia has a platform for the controlled and precise assembly of lipid nanoparticles (LNPs) and machinery for rapidly scaling nanoparticle formulations for late pre-clinical development. It's a state-of-the-art facility designed for success…your success.

Services Tailored to Client Needs

Ascendia's pharmaceutical contract manufacturing services include:

Full-scale LNP Manufacturing Capabilities

Aseptic (Sterile) and Non-sterile Manufacturing Environments

Phase 1, Phase 2, and Phase 3 (Clinical and Commercial) Manufacturing Capacities

Lyophilization (e.g., freeze-drying), spray drying, nanomilling, homogenization, extrusion, and other advanced capabilities available in our Class 10,000 (ISO 7) and Class 100 (ISO 5) pharmaceutical manufacturing facilities.

The Ascendia Advantage: Your Partner of Choice at Every Phase

Ascendia has become a Partner of Choice with many drug companies during the pre-formation and formulation stages.

That expertise and our BEST (Brilliant technology, Excellent service, Superior quality, and Trust) philosophy carry over to our manufacturing processes.

That proficiency and approach further the inherent benefits of using one CDMO from pre-formulation and discovery through Phase 3 and commercial supply for biotech and pharma companies. We refer to those benefits as “The Ascendia Advantage.” Frequently, companies that utilize Ascendia services end-to-end experience three things:

Faster times to market.

Greater confidence in drug performance and quality.

Lower drug formulation development costs.

Ascendia also offers a unique advantage for drug development projects utilizing LNPs. Ascendia is the only North American CDMO that can provide LNP services from pre-formulation through Phase 3 and commercial supply utilizing microfluidic chip mixing technology.

This distinct offering sets us apart and ensures that you're making an innovative and strategic choice for your project when you choose Ascendia.

We've never had a microbial excursion, thanks to our colleagues' exceptional hygienic habits and careful environmental monitoring (EM). However, effective pharmaceutical contract manufacturing requires more than diligent EM. It requires the right equipment, the right partner, and the right expertise—it requires Ascendia.

Reach Out Today

By choosing to partner with Ascendia, you're not just getting a service provider. You're gaining the ability to make informed decisions, mitigate risks, and confidently bring high-quality pharmaceutical products to market. We’ve designed our services to instill optimism in the success of your projects, making us the ideal partner for your biopharma development needs.

Contact us today to learn more about how Ascendia can drive the success of your pharmaceutical development programs. Let us be your trusted partner in ensuring the stability and safety of your products.