State-of-the-Art Pharmaceutical Manufacturing Facility

Ascendia Pharmaceutical Solution’s expansive 60,000-square-foot state-of-the-art facility in North Brunswick, NJ has sterile and non-sterile manufacturing capabilities for small molecule and biologic projects. Manufacturing is housed in the same location as our formulation development, analytical testing, and other services, creating a convenient “one-stop shop” for numerous benefits for clients.

Equipment and Services

Our Pharmaceutical Manufacturing Capabilities

Ascendia supports multiple dosage forms through its Class 10,000 (ISO 7) and Class 100 (ISO 5) cleanrooms for cGMP manufacture of sterile products, and Class 100,000 (ISO 8) manufacturing suites for production of non-sterile dosage forms. Ascendia is qualified to produce Phase I/II/III clinical trial materials and has self-contained isolators for use with high potency compounds and/or aseptic processing.

-

Manufacturing

Sterile Nano-suspension Manufacturing

Ascendia is the only U.S.-based CDMO, who owns the NETZSCH Group Vakumix solution for aseptic wet milling process. It allows us to address the complex aseptic manufacturing for nano-suspensions and micron suspension formulations. Our aseptic suspension manufacturing process includes in-line Rotor-Stator homogenization and wet medium milling that results in sterile, high drug concentration, stable suspension for use in long acting injectables, intravitreal, IV, topical, and IM administration.

-

Specialized Equipment

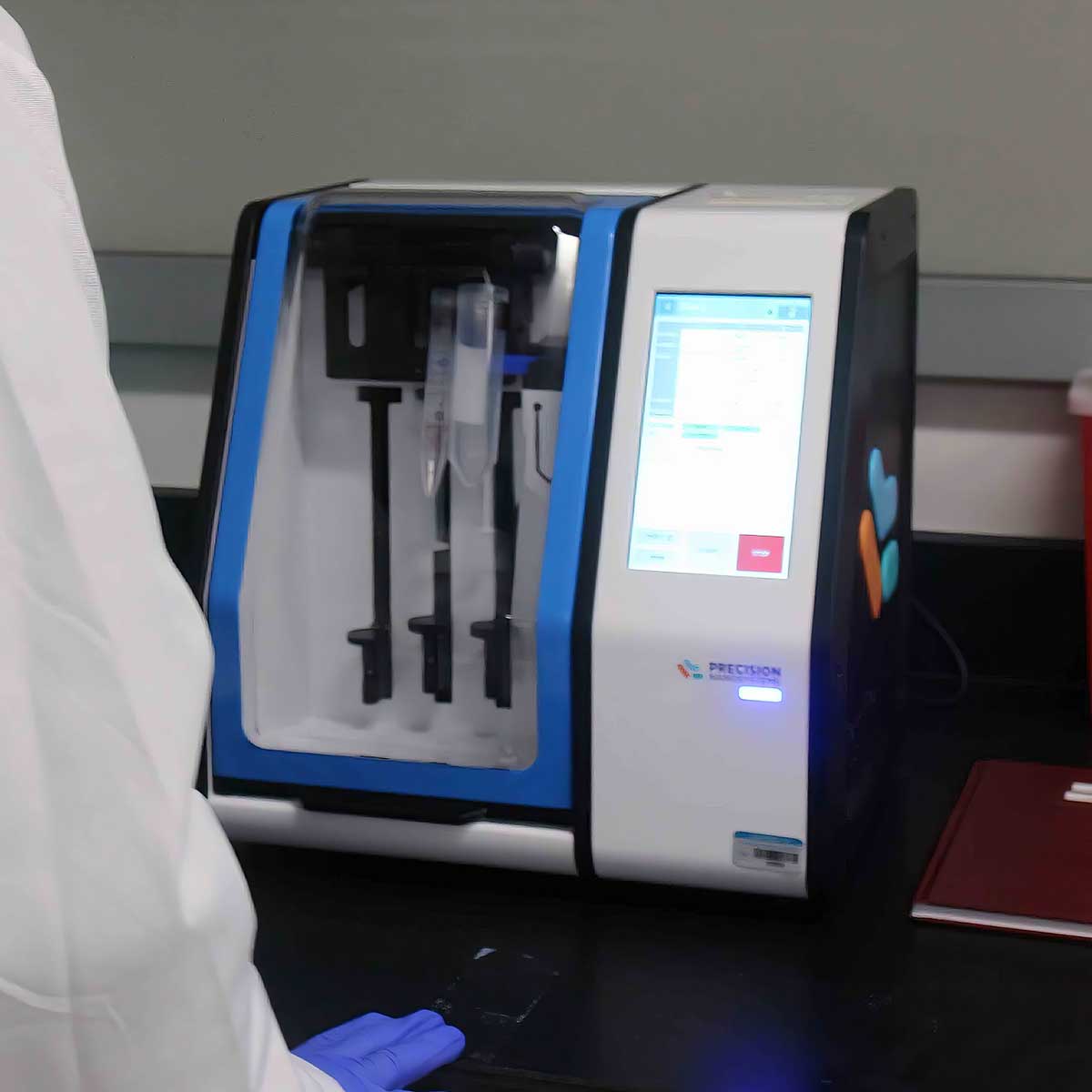

LNP Manufacturing

Ascendia has integrated Precision Nanosystems’ NanoAssemblr® GMP System into its LNP manufacturing process. Drug development timelines are expedited via a seamless scale-up process to minimize engineering batches and de-risk manufacturing under cGMP conditions for robust and reproducible results.

-

Spray Drying Services

Your ‘Go-To’ CDMO Partner

Ascendia is your CDMO for pilot spray drying in different environments. Our expertise, including transitioning formulations from non-cGMP to cGMP environments at small or pilot scale, allows for a seamless transition to pharmaceutical companies for larger scale production.

-

Pre-clinical to Phase 3

Comprehensive Manufacturing Services

Ascendia manufacturing services are available to pharma and biopharma companies that seek a CDMO as their formulation transfers from a preclinical to Phase 3 and commercial supply. Ascendia can transition quickly to cGMP manufacture of first-in-man clinical materials.

Benefits of Working with Ascendia

Drug Development Experts

One-stop Convenient Location

On-schedule; Within Budget

- Faster times to market

- Greater confidence in drug performance

- Lower drug formulation development costs

Subscribe to Email Updates

Learn More About Ascendia’s Expertise

Get our latest news and insights in your email inbox.